The development of electric vehicles depends not only on the promotion of policies, but also on the continued cost reduction of power batteries. Here we study the cost structure of power batteries.

In the power battery cost model, we split the cost of the power battery pack into material cost and production cost. The material cost includes cell material, module material and battery pack material. The production cost includes labor cost, depreciation and other manufacturing costs.

We refer to ANL's costing model and select prismatic battery pack for cost splitting. According to our calculations, the current cost of ternary 523 and LFP battery is 486.96 and 374.44 Yuan/kWh when considering only battery cells. When considering modules, pack and battery systems, the total power cost of ternary 523 and LFP battery system is 724.91 and 612.40 Yuan/kWh, respectively. (Note: This calculation is mainly based on providing model ideas, and the specific values may deviate from the actual situation)

There are certain differences in the cost of power batteries under different positive and negative electrode materials. Overall, the cost of materials accounts for a relatively large amount, and labor costs, depreciation and other manufacturing costs account for a relatively small amount. The material cost is mainly based on positive and negative materials, separators, the electrolyte and components are the main ones.

Let's assume that the electric charge of an electric car is 60kWh, including 1 battery pack, 20 modules and 240 cells. The above assumptions are mainly used to estimate the cost of modules and pack components. We selected ternary 523 and LFP battery as the research objects for analysis and comparison. With reference to public data, we assume that the actual gram capacity of ternary (523) cathode material is 157mAh/g; the actual gram capacity of the domestic lithium iron phosphate cathode material has basically reached 150mAh/g, we take the average level of 145mAh/g as the assumption of the actual gram capacity of the lithium iron phosphate cathode material; we assume that the actual gram capacity of the negative electrode active material (artificial graphite) is 350 mAh/g.

The positive electrode material includes a positive electrode active material, a positive electrode carbon additive (conductive agent), a positive electrode binder, a positive electrode current collector (aluminum foil), and a positive electrode assembly positive electrode terminal. According to our calculations, the current cost of ternary 523 positive electrode active material, conductive agent, adhesive, aluminum foil, and positive terminal is 195.25, 1.81, 5.42, 6.08, 6.53 Yuan/kWh, and lithium iron phosphate batteries are 73.59, 2.19, 6.57, 6.74, 6.55 Yuan/kWh, active materials account for the vast majority of the cost. Taking into account the material loss, we calculated that the total cost of ternary 523 positive electrode materials is 238.99 Yuan/kWh, and the total cost of lithium iron phosphate positive electrode materials is 106.27 Yuan/kWh. In recent years, the price of lithium iron phosphate has fallen rapidly, and the price of ternary cathode materials is relatively small due to the relative scarcity of precious metals.

The anode material includes an anode active material, an anode binder, an anode current collector (copper foil), and an anode terminal of an anode assembly. According to our calculations, the current cost of ternary 523 negative electrode active material, binder, copper foil, and negative terminal are 48.66, 0.99, 41.37, 19.32 Yuan/kWh, and lithium iron phosphate batteries are 52.27, 1.07, 45.81, 19.54Yuan/kWh, the cost of active materials, copper foil and negative electrode terminals in the negative electrode material is relatively high, and the binder accounted for relatively low. Taking into account the material loss, we have calculated that the total cost of ternary 523 anode materials is 122.59 Yuan/kWh, and the total cost of lithium iron phosphate anode materials is 131.87 Yuan/kWh. Due to the difference in energy density and the proximity of other materials, the anode material cost of lithium iron phosphate batteries is higher than that of ternary batteries.

The cost of electricity of the ternary and lithium iron phosphate battery separators is relatively close, ternary is 31.29 Yuan/kWh, and lithium iron phosphate is 34.86 Yuan/kWh. The difference is also that the energy density of the lithium iron phosphate battery is lower, which leads to more materials than ternary.

The electrolyte content in the cell material is slightly lower than that of the separator. The unit cost of ternary 523 electrolytes is 20.93 Yuan/kWh, and lithium iron phosphate is 25.28 Yuan/kWh.

In addition to the above, the other costs of the battery cell mainly include the outer shell and the thermal conductive sheet, and the overall cost is relatively low. The cost per kWh for ternary 523 and other battery materials for lithium iron phosphate batteries are 12.18 and 12.69 Yuan/kWh, respectively.

Following the process sequence, the cell is followed by the module and the PACK. The module material includes the voltage controller, module terminals, module housing, and module connector. The PACK material mainly includes the PACK terminal, bus bar, and PACK housing. According to our calculations, the cost of module materials and PACK materials for ternary 523 batteries are 102.8 and 58.15 Yuan/kWh, and those of lithium iron phosphate are 105.77 and 58.19 Yuan/kWh, respectively. So far, we have completed the calculation of the total material cost of PACK, and after summing up, the total power cost of all materials of PACK of ternary 523 and lithium iron phosphate is 586.92 and 474.93 Yuan/kWh, respectively. Considering the cost of battery management system and thermal management components, we have calculated that the current total electricity cost of ternary 523 and lithium iron phosphate battery system materials is 660.92 and 548.93 Yuan/kWh, respectively.

The production cost of power batteries includes labor costs and manufacturing costs. Manufacturing costs include equipment and building depreciation and other manufacturing costs. We assume that the investment of 1GWh production capacity equipment is 300 million Yuan, 400 people, 300 days per year, 8 hours per day, labor hours is 96,000 hours/year, and working hours are 25 Yuan/hour, corresponding to 24 million Yuan/year. Labor cost 24 Yuan/KWh; equipment depreciation period is 8 years, annual depreciation rate is 12.5%, and equipment depreciation is 37.5 Yuan/KWh; single GW production line covers an area of 4,500 square meters, and housing construction fixed asset expenditure is 15,000 Yuan/square meter Meters, the depreciation period is 20 years, the annual depreciation rate is 5%, and the depreciation of house construction fixed assets is 3.38 Yuan/KWh. Overall, we calculated that the KWH cost of ternary 523 and the lithium iron phosphate battery were 24 Yuan/KWh respectively, the KWH cost corresponding to depreciation was 40.88 Yuan/KWh, and the KWH cost corresponding to other manufacturing costs They are all 11.29 Yuan/KWh.

In summary, when only considering the battery core, the cost of electricity of ternary 523 and lithium iron phosphate batteries is 486.96 and 374.44 Yuan/kWh, respectively. In consideration of the module, PACK and battery system, the total power cost of ternary 523 and lithium iron phosphate battery system is 724.91 and 612.40 Yuan/kWh, respectively.

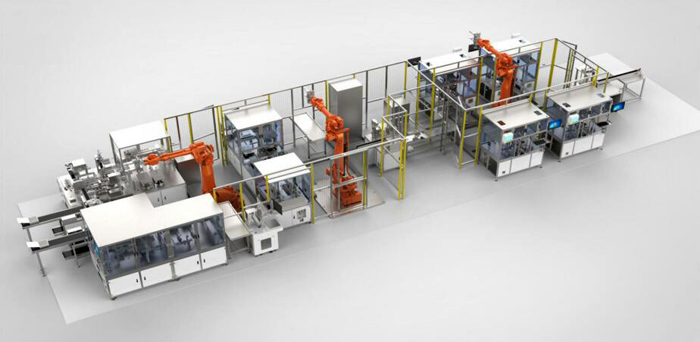

Founded

in 2011, Xiamen WinAck has always focused on

the R&D, production and sales of battery

pack assembly machine and battery

test equipment. The

main business is to provide solutions for the battery pack assembly line, include: battery insulation paper

sticking machine, battery sorting machine, battery spot welding machine,

battery test equipment, battery PCM/BSM tester…

We welcome your inquiry, whether it is battery pack assembly manufacturing or battery testing equipment, we will provide you with a suitable solution.

Contact: Rudy Yan

Phone: 0086- 188 0506 7911

Tel: 0086-592-7297239

Email: rudy@winack.com

Add: WinAck Group, Xiangbei Industrial Zone, Xiamen City, China