The evaluation indicators of power battery manufacturing capacity mainly include battery manufacturing qualification rate, material utilization rate, labor cost rate, WH manufacturing cost, safety index, energy consumption index, operation reliability, etc., of which battery manufacturing qualification rate and material utilization rate are the focus of attention.

At present, large-scale manufacturing of power batteries still faces many challenges, mainly in many areas such as standardization, quality and cost.

1. Standardization, which is the basis of large-scale manufacturing. Its degree determines the cost and quality qualification rate of the product, and the main areas involved include size specification standards, manufacturing processes, and material standardization.

There are a wide variety of battery cell sizes, and different battery types have different specifications. After standardizing the size type, size quantity, interface, etc., not only can the pass rate be increased, but the cost is expected to drop by 20-30%.

2.The manufacturing quality of automotive-grade power batteries is lacking. The manufacturing qualification rate of power batteries is the key to the survival of power battery companies, not only related to the cost of manufacturing companies, but also related to the safety of power batteries.

At present, the global power battery manufacturing qualification rate is still at the B level, and the CPK is between 1.0 and 1.33. The manufacturing process will contain hidden variations and safety hazards. More stringent screening and testing standards need to be adopted, and various resources and methods need to be used to upgrade it to A level.

The goal is that the vehicle-level power battery manufacturing standards require the CPK level to be 2.0 and above, so as to ensure that the batteries produced can be loaded into vehicles.

3. The savage growth of power battery manufacturing equipment. The entire process of generating new process equipment, including process research, index verification, prototype development, and mass production manufacturing, still does not have a unified platform to plan the entire manufacturing process.

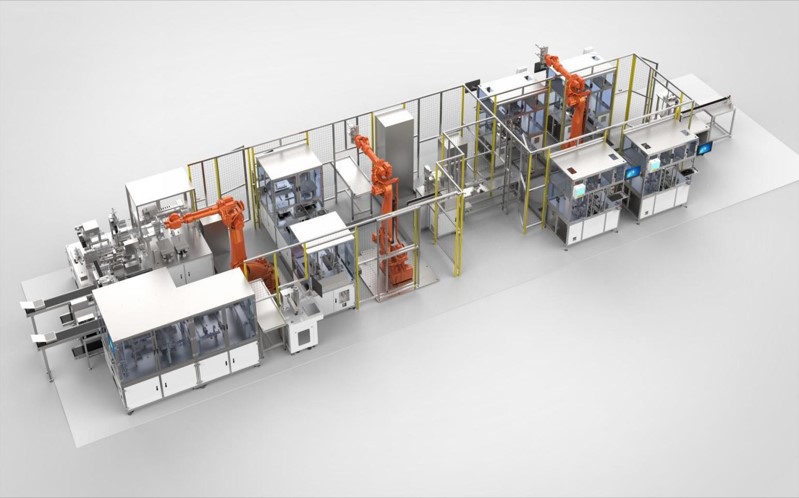

Establish a unified process platform, and focus on the pole piece manufacturing process and equipment research and development platform, battery cell manufacturing process and equipment research and development platform, module PACK manufacturing process and equipment research and development platform, battery recycling process and equipment research and development platform, and intelligent manufacturing system platform And solid-state battery technology and equipment platform.

The future of battery manufacturing is a trillion-scale industry, and equipment should be fully valued as an independent industry and system planning.

Contact: Rudy Yan

Phone: 0086- 188 0506 7911

Tel: 0086-592-7297239

Email: rudy@winack.com

Add: WinAck Group, Xiangbei Industrial Zone, Xiamen City, China