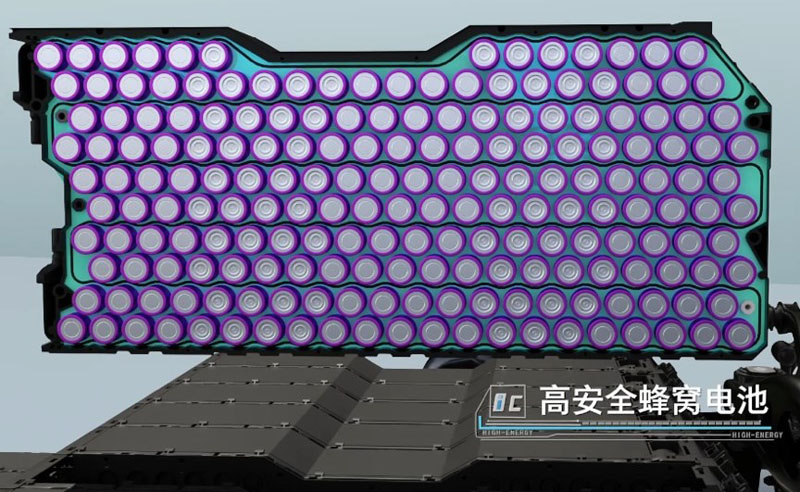

On March 5, 2020, the cellular battery technology launched by JAC New Energy is called UE (Unitized Encapsulation) module technology, also known as epitaxial encapsulation module technology. All the batteries in the battery pack are covered with lightweight self-leveling thermal conductive adhesive 360°, and the heat exchange area of the batteries is more than 14 times that of the square battery and the soft battery.

From the appearance, the shape of the battery module is similar to the shape of a bee honeycomb. The light weight self-leveling thermal conductive adhesive wrapped by the outer layer of the battery core of the UE module technology is like placing the battery cell in a constant temperature nursery room. , Always keep within the fixed temperature range, to ensure that the battery core is carefully cared like a baby bee.

The combination of the honeycomb battery and intelligent temperature control technology realizes that the temperature of all cells in the battery pack is always maintained in the optimal working range. In order to meet the long-distance driving, high-speed + fast charge requirements for battery heat dissipation, ensure the safety of the vehicle.

The honeycomb battery is a small energy battery used when the battery is selected. Even if a single battery loses heat, the lithium battery pack and the vehicle will not catch fire. The cells of the honeycomb battery are arranged in a hexagon, and the cells are filled with thermally conductive glue, which ensures the heat dissipation speed of the cells. 100% contact between the thermal conductive adhesive and the battery core will speed up the heat dissipation of the battery core. The electrochemical reaction of the battery cell inevitably brings heat dissipation, and the thermal conductive glue quickly transfers the heat out, ensuring that the temperature difference inside the battery pack is ≤3°C.

The cells of the honeycomb battery are filled with thermally conductive glue to achieve electrical and thermal isolation between the lithium battery cells. If a cell fails, it will not spread to the surrounding area, so it will not cause a chain reaction.

The honeycomb battery adopts 21700 NCA battery, this battery adopts double explosion-proof valve design, the capacity is 1C-4.8Ah (0.2C-5Ah), and the single cell energy density is 245wh/kg. From the perspective of energy density, the energy density of cellular batteries conforms to the mainstream trend and is in the middle and upstream levels.

Another key point of the honeycomb battery is that the electric cell adopts double explosion-proof valves. In the past, cylindrical batteries had only one explosion-proof valve at the top of the cell. Once the thermal runaway occurs inside the cell, the reaction is very violent. Only one end is designed with a valve, which means that the gas can only flow out from one direction. Adopt double explosion-proof valve design to shunt out gas and reduce the severity.

Why use NCA (nickel cobalt aluminum), Zhou Peng told reporters that NCA batteries have better safety and stability than NCM (nickel cobalt manganese) batteries, but the technical difficulty is also greater. This difficulty covers material technology, battery design and processing technology. The battery that Panasonic supplies to Tesla is NCA. Although Tesla has a fire accident, the proportion of fire accidents in domestic electric vehicles is significantly lower than that inChina.

Five-level battery thermal runaway safety development process

Based on the cylindrical battery, JAC New Energy has also established a five-level battery thermal runaway safety development process, ensuring the comprehensive development of thermal runaway safety from the level of batteries, modules, simple battery packs, battery packs, and complete vehicles.

The first level: batteries, JAC joint suppliers design battery shell material, thickness, positive and negative electrode explosion-proof pressure, shell production stretching process control and other technical solutions, to achieve directional blasting of the battery, to prevent side blasting and casing Local melting holes.

The second level: modules, through the module's electrical isolation and thermal insulation solutions to achieve a controlled release of energy after the explosion of a single cell.

The third level: simple battery pack, through module protection, battery pack exhaust path design, to achieve safe isolation between adjacent modules.

The fourth level: battery pack, through the body integrated high-strength battery shell and bottom protection design, to ensure that the battery pack structure is safe and reliable under the extreme working conditions of the vehicle.

Fifth level: Complete vehicle, through the integrated vehicle thermal management system design, complete vehicle control system design, real-time monitoring of the battery pack safety status, the battery can be turned on immediately after the explosion of the cooling system to reduce the battery pack temperature. At the same time, the battery failure is reported to the remote monitoring system, which will not cause the vehicle to catch fire and ensure the absolute safety of the vehicle and personnel.

What are the advantages of Cellular Battery?

1. Safety performance: The honeycomb battery adopts the design of multiple independent cells, combined through the structure of the honeycomb, even if a certain cell is thermally out of control, it will avoid the entire fire of the battery pack because of this structure. Cellular batteries have passed many rigorous tests. It is heated directly with gasoline from the bottom for 130 seconds continuously; directly touches the battery pack with flames and burns continuously for 130 seconds. In these extreme tests, cellular batteries have withstood the test.

2. Endurance: The energy density of the cellular battery is higher than that of the general power battery, because the size of the overall cell is smaller, and the module structure is more flexible. The combination of the cellular structure greatly improves the maximum energy of the battery pack. The core heat exchange area is more than 14 times that of other domestic products, and the endurance is up to 530KM, which is an absolute leader in the performance of many power batteries.

3. Use climate requirements: Cellular batteries can be said to be available 24/7, similar to the structure of a honeycomb, which greatly reduces the energy attenuation caused by the temperature of the battery core. Similar to the hive, the bees always maintain a suitable temperature, which is conducive to exerting the best performance; the lithium battery heats up quickly at low temperatures in winter, reducing the cruising range, and the battery cools down quickly at high temperatures in summer, effectively extending the battery life.

At the same time, the honeycomb battery has passed the extreme safety verification of -40 ~ 80 ℃ temperature and humidity cycle, 130s fire, 200KN extrusion and 1m water depth continuous immersion for 12h, and its performance is very good. The technology of power lithium batteries is changing rapidly, and new technologies are emerging one after another. However, in the case of universal pursuit of energy density, honeycomb batteries focused on the improvement of safety technology obviously have more important meanings.

Founded in 2011, WinAck Battery has always focused on the R&D, production and sales of battery pack assembly machine and battery testing equipment. The main business is to provide solutions for the lithium battery pack assembly production line.

Contact: Rudy Yan

Phone: 0086- 188 0506 7911

Tel: 0086-592-7297239

Email: rudy@winack.com

Add: WinAck Group, Xiangbei Industrial Zone, Xiamen City, China