Product description:

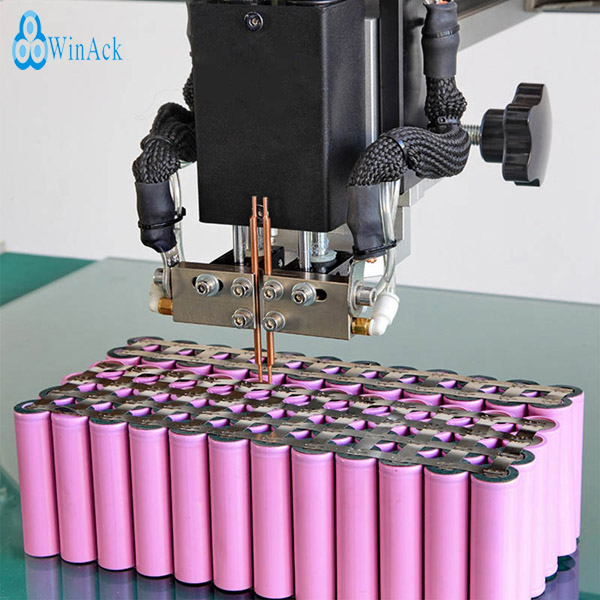

This battery spot welder machine is suitable for welding battery cell-to-cell connections with solid welding, no discoloration of the welding joints, elimination of the grinding process and high welding efficiency.

In addition, the welding machine draws power from the power grid instantaneous power is low, the power factor is high, the impact on the power grid is small, energy saving; the output voltage is stable, good consistency.

Features:

1. The battery spot welder is controlled by a built-in microcomputer with a large LCD screen that graphically displays the current working status in real time.

2. The welding procedures are set up digitally for easy and fast operation.

3. The welding voltage lockout technology prevents fluctuations in AC input grid voltage from affecting welding current.

4. The pulse width of spot welding is adjustable, the spatter is small when spot welding, and the welding joints are not discolored.

5. The battery spot welder machine has three pulse modes: single-pulse spot welding, double-pulse spot welding and triple-pulse spot welding. The first pulse mainly serves to preheat and remove surface dirt, the second pulse is the main welding pulse, and the third pulse is to repeat the second pulse.

6. A total of 10 sets of welding procedures can be stored for quick switching when spot welding different products.

7. The 18650 battery spot welder has the function of monitoring and comparing the welding current, and the sound and light alarm when the current is abnormal, which can effectively prevent the false welding.

8. Equipped with a 5-digit counter to count the number of successful welds, and a count alarm can be set to indicate the need to repair the welding needles.

9. The battery spot welder has a fault self-diagnosis function to display specific faults for easy maintenance.

Scope of application:

This battery spot welder machine is particularly suitable for the welding of precision parts, such as the pure nickel sheet and nickel-plated steel strip of lithium-ion battery packs.

The welding method is available in single point or continuous point. High welding accuracy, good welding quality, low splash during welding, no discoloration of welding joints.

Technical specifications of 18650 Battery Spot Welder Machine

Product name | Battery Spot Welder Machine |

Product model | WA-SW-M50CN |

Welding speed | 0.8~1.2s/Single-spot |

AC Input voltage | 220VAC±10% / 50Hz±2Hz |

| Energy storage capacitors | 6600uf |

Rated power | 300W |

| Maximum output current | 5000A |

Maximum power output of the transformer | 20KVA |

Control mode | Fixed voltage control |

Pre-welding voltage | Adjustment range: 80V~330V Accuracy: 0.5V |

Welding voltage | Adjustment range: 80V~330V Accuracy: 0.5V |

Welding time | Adjustment range: 1.0ms~20.0ms Accuracy: 0.1ms |

Welding pulses | Single-pulse mode Double-pulse mode Triple-pulse mode |

Welding needle configuration | 1.8mm or 3mm or 6mm |

Debugging Spacing of Welding Needles | 0~20mm |

Welding material | Pure nickel sheet or Nickel-plated steel strip |

Thickness of nickel-plated steel strip | 0.08~0.30mm |

Thickness of pure nickel sheet | 0.08~0.20mm |

No. of storable welding procedures | 10 sets |

Size(L*W*H) | 1000*600*1310mm |

Overall weight | About 100KG |

Contact: Rudy Yan

Phone: 0086- 188 0506 7911

Tel: 0086-592-7297239

Email: rudy@winack.com

Add: WinAck Group, Xiangbei Industrial Zone, Xiamen City, China