Product description:

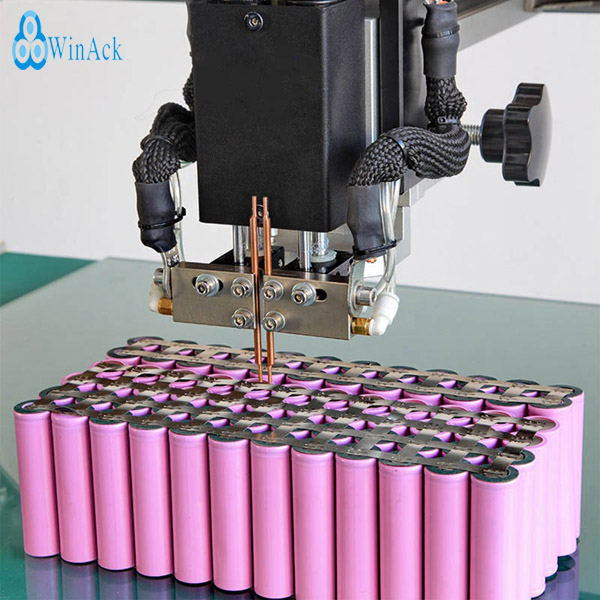

This battery spot welder is a high-frequency pulse precision spot welder with adjustable welding pulse width and good welding performance for lithium ion battery pack assembly.

This transistor spot welder is an upgraded version of the capacitor discharge spot welder. Traditional capacitive spot welding machines control the size of the discharge current by charging and discharging the capacitor, and since its discharge time cannot be precisely controlled, a transistor switch (FET switch) has been added for precise control.

This battery spot welder uses a single chip machine to control the FET switch to precisely control the welding current and ensure welding performance.

Features:

1. Welding current rises quickly and can be precisely controlled.

2. Constant current control, constant voltage control, and mixed voltage and current control can be used to select the appropriate control method according to welding requirements.

3. The display simultaneously displays real-time dynamic curves of current, voltage, resistance, power and heat for easy control of weld quality management.

4. The real-time dynamic list displays the latest 10 weld monitoring data for each joint simultaneously.

5. It is equipped with a pre-power detection function to determine the condition of the weld path work piece.

6. RS232/485 communication functions as standard.

7. The welding pulse width is adjustable, the welding spatter is small, and the welding point does not change color.

Scope of application:

Battery spot welding machine for battery pack welding, it is suitable for welding 18650, 21700, 26650 and 32650 battery packs, such as E-bike battery, EV battery, power tool battery, energy storage battery , street light battery, car start and stop battery.…

Battery Spot Welding Machine for Battery Pack Assembly Parameters

|

Product name |

Battery Spot Welding Machine |

|

Product model |

WA-SW-60B |

|

Control mode |

A: fixed current control B: fixed voltage control C: fixed current and voltage control |

|

Input voltage |

220V±10% / 50Hz±10% |

|

Rated power |

425W |

|

Maximum output current |

6000A |

|

Current waveform |

+/- , -/+, +/+, -/- |

|

Setting range of current |

0.6~6.0KA |

|

Setting range of voltage |

0.1~9.0V |

|

Electric current monitoring range |

0.00~9.99KA |

|

Voltage monitoring range |

0.00~9.99V |

|

Welding needle configuration |

1.8mm or 3mm or 6mm |

|

Debugging Spacing of Welding Needles |

0-20mm |

|

Welding material |

Pure nickel sheet or nickel-plated steel |

|

Parameter store |

30 groups |

|

Size(L*W*H) |

182*502*479mm |

|

Overall weight |

28KG |

Contact: Rudy Yan

Phone: 0086- 188 0506 7911

Tel: 0086-592-7297239

Email: rudy@winack.com

Add: WinAck Group, Xiangbei Industrial Zone, Xiamen City, China