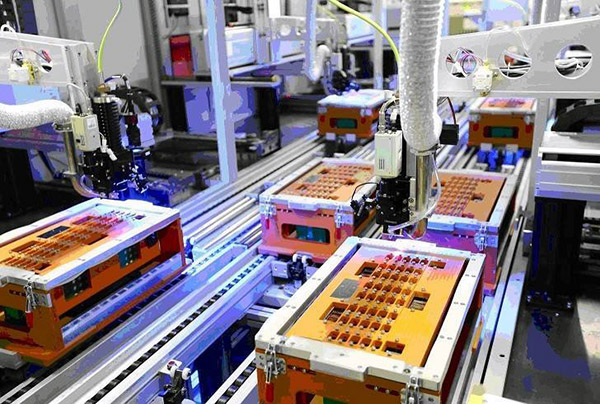

At present, battery laser welder has been widely used in lithium battery cell manufacturing, lithium battery module assembly and lithium battery pack production lines.

The welding process directly affects the conductivity, safety, module strength, air tightness and corrosion resistance of lithium batteries. For example, in the connection of the battery module and the battery cell, the level of the welding process directly determines the electrical conductivity and safety level of the battery module.

The lithium battery laser welding system is mainly composed of laser source, laser welding head, auto focus adjustment system, visual positioning system, welding table, CCD monitoring system, dust collector and water cooler.

Among them, there are two common welding heads in the laser welding system, one is a common laser welding head, and the other is a galvanometer welding head. The common laser welding head is driven by a moving platform, while the galvanometer welding head is driven by a motor. In comparison, the galvanometer welding head has unique advantages in terms of use efficiency and technical process.

1) Ordinary laser welding heads are compact in structure, and the welding is driven by a three-axis motion platform. The speed is usually limited, and the speed range of motion is only 0~200mm/s. The galvanometer welding head is driven by the high-speed oscillation of the motor, and the speed range can achieve 0~2000mm/s.

2) When welding complex trajectories such as triangles, circles, and S shapes, ordinary welding heads often stop at the corners, resulting in inconsistent welds. The galvanometer laser welding head is not limited by the motor speed of the three-axis motion platform, and flexibly realizes high-speed welding of a wide range of arbitrary curves in the plane.

3) For the side plate welding of lithium battery modules, the porosity of ordinary laser head welding is generally 20% ~ 30%, while the porosity of galvanometer laser welding head is only less than 2%.

With the continuous improvement of the performance and cost requirements of power batteries in the new energy market, the efficiency and cost advantages of galvanometer laser welding systems in the production of lithium batteries have begun to continue to highlight.

Contact: Rudy Yan

Phone: 0086- 188 0506 7911

Tel: 0086-592-7297239

Email: rudy@winack.com

Add: WinAck Group, Xiangbei Industrial Zone, Xiamen City, China