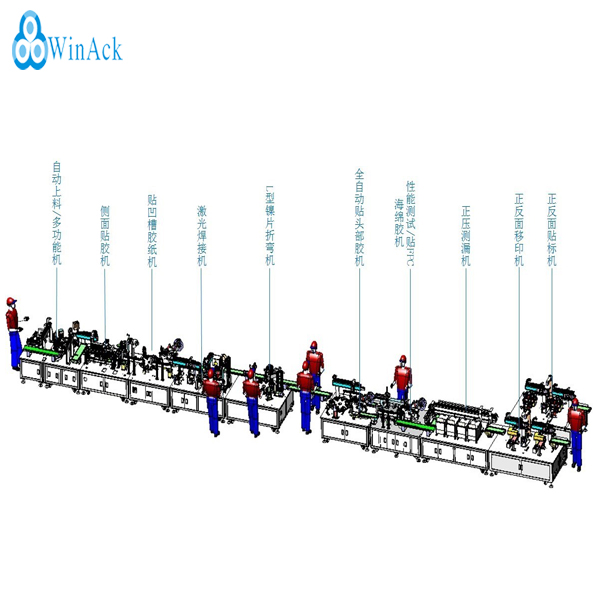

The mobile phone battery pack assembly line uses pouch battery cells and PCM as the core raw materials and is assembled into a finished cell phone battery through a series of processes.

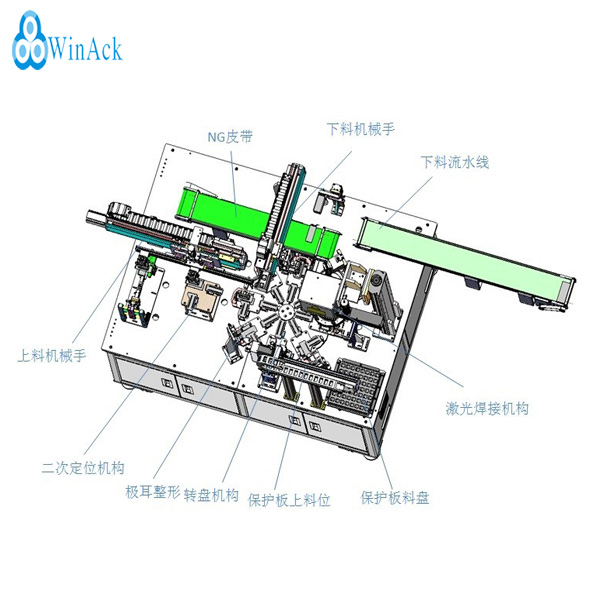

The cell phone battery production line is mainly used to complete the automatic feeding of pouch battery cells, tab shaping, OCV/IR testing, data uploading MES system, tab cutting, tab shaping, high temperature tape on the groove, side tape wrapping, shaping, PCM welding, sticking high-temperature tape, L-shaped nickel sheet bending, FPC bending, manual mounting of plastic shell, head molding tape (vest label), head molding tape package, finished battery test, FPC sticking sponge tape, positive pressure leakage test, tape on the front and back, pad printing on the front, baking, pad printing on the back, etc.

Features:

1. Flexibility: Compatible with a variety of battery products, with extensive compatibility.

2. Convenience: Convenient operation, easy-to-understand operation interface, convenient model change, few manual adjustment parts, and simple adjustment.

3. Economy: The structure of the entire production line has been optimized, the structure is simple and durable, and there are few wearing parts. The key components (such as cutters) are made of high-tech materials, and the service life is 50% longer than similar products.

4. Security: There are multiple security protections such as hardware protection and software protection.

5. Expansibility: There are multiple equipment interfaces, which is convenient for equipment retrofitting, upgrading and interconnection (MES).

6. Maintainability: The equipment is easy to maintain and the professional after-sales team can provide services.

Scope of application:

The mobile phone battery production line has a high degree of flexibility and is compatible with various sizes of battery products.

|

Battery size |

Height |

40~130mm |

|

Width |

30~70mm |

|

|

Thickness |

2.5~10mm |

|

|

Tab length |

4~20mm |

|

NO. |

Items |

Parameter |

|

1 |

UPH |

≥900PCS/H |

|

2 |

Battery size |

Height:40~130mm |

|

Width: 30~70mm |

||

|

Thickness: 2.5~10mm |

||

|

Tab length: 4~20mm |

||

|

3 |

Power supply |

AC220V (±10%) / 50 HZ |

|

4 |

Input gas source |

0.5~0.6MPa |

|

5 |

Power |

≤20KW(MAX) |

|

6 |

Area to weight ratio |

≤500kg/M² |

|

7 |

Utilization rate |

≥98% |

|

8 |

Rate of qualified products |

≥98% |

|

9 |

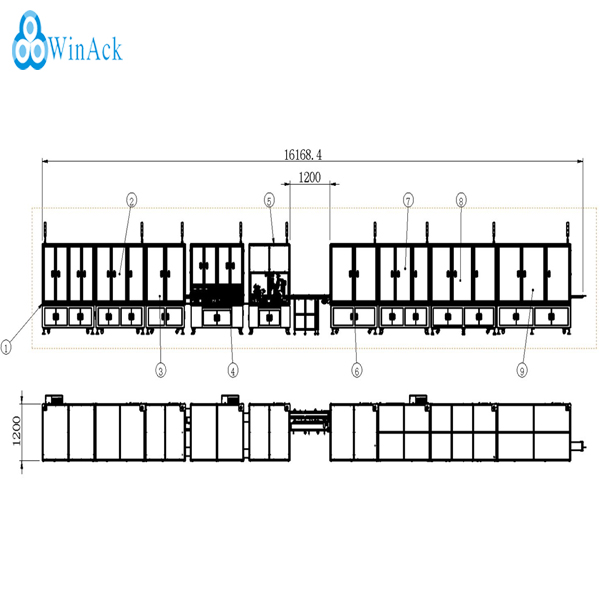

Production line size |

L*W*H: 16.0m * 1.2m * 1.9m |

Contact: Rudy Yan

Phone: 0086- 188 0506 7911

Tel: 0086-592-7297239

Email: rudy@winack.com

Add: WinAck Group, Xiangbei Industrial Zone, Xiamen City, China