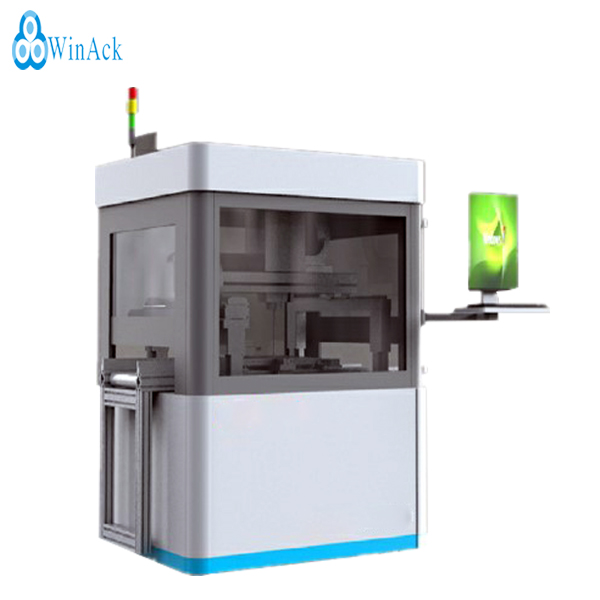

Product description:

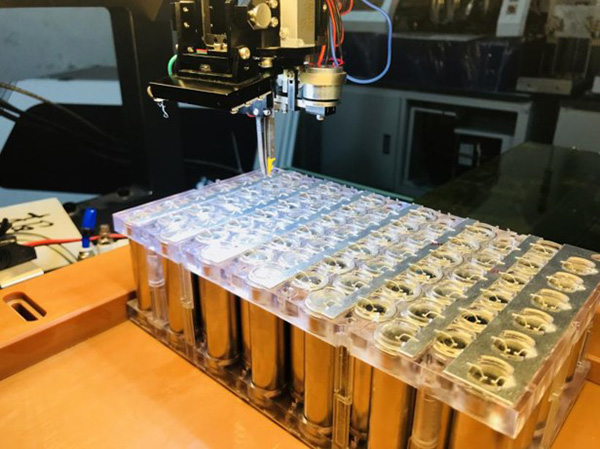

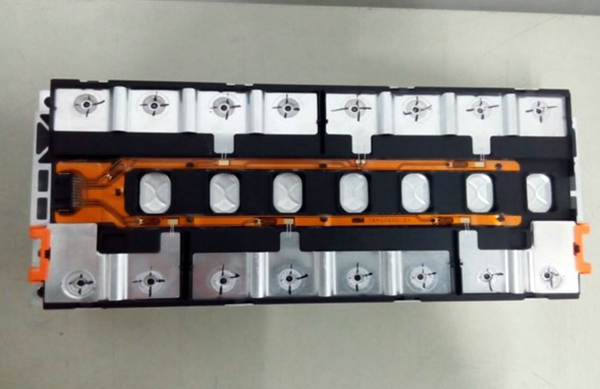

After the battery module assembly process is completed, it is loaded by the automatic feeding system of the ultrasonic welding equipment & Al wire bonding machine, and then transferred to the ultrasonic welding area, and the welding head system performs ultrasonic welding according to the set welding parameters and positions. After the ultrasonic welding is completed the battery module is transferred to the designated position through the automatic feeding system, and the equipment operator takes the welded battery module away and sends it to a next production process processing.

Features:

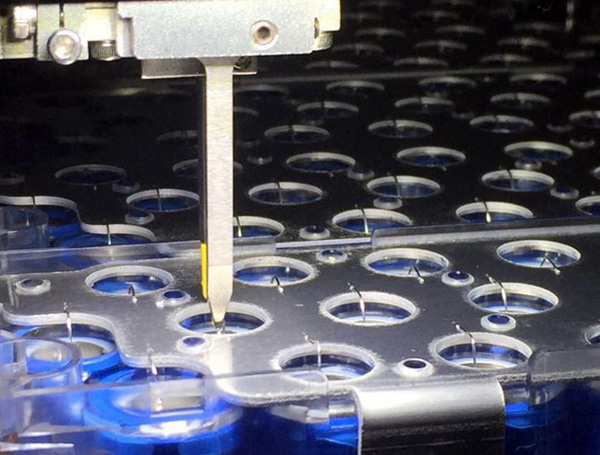

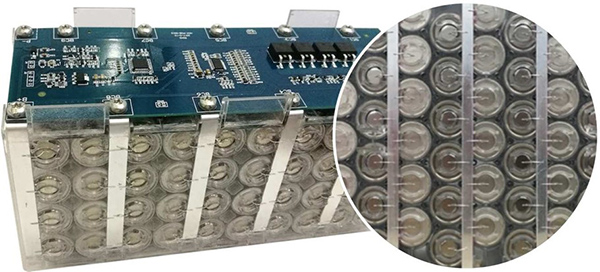

1. Lead connection process, bonding aluminum wire can directly act as a fuse, and will automatically fuse in the event of a short circuit to ensure the safety of the battery pack.

2. The aluminum wire can match the stress requirements and tensile test requirements of the battery pack on the connection.

3. The use of aluminum wire bonding can achieve repeated welding, greatly improving the maintainability and recovery rate.

4. When using aluminum wire welding or aluminum strip welding, the temperature of the welding zone will not rise. Other traditional welding methods require heating to melt the metal.

5. Al wire bonding is a clean welding process. There are no flux residues or molten metal slag, avoiding reliability problems.

6. The battery pack welding quality inspection machine can accurately and quickly detect whether there is a problem with the connection between the battery and the busbar.

7. It is easy to detect if welding defects occur during aluminum wire welding, and it is easier to repair the defective positions without welding damage.

Scope of application:

The fully automatic wire wedge bonder is suitable for the lithium-ion battery pack production for the lead connection between the battery cell and the busbar, and the sampling connection of battery cell status.

It has applications in cylindrical battery packs, prismatic battery packs and pouch battery packs.

Test items of the battery pack Al wire bonding machine

|

Product name |

Fully Automatic Wire Wedge Bonder |

|

Product model |

WA-UW-3000XK |

|

Input voltage |

220V, 50/60Hz |

|

Power |

3000 W |

|

Input gas source |

0.5MPa |

|

X-axis travel |

400MM (Customizable) |

|

Y-axis travel |

800MM (Customizable) |

|

Z-axis travel |

60MM (Customizable) |

|

Rotary-axis |

±220°(Resolution: 0.08°) |

|

Transducer |

60KHz (Customizable) |

|

Heavy wire welding head |

Rotatable, standard front cutter |

|

Welding pressure |

50~1500 grams |

|

Maximum arc height |

40 mm |

|

Wire feeding system |

Motor controlled wire feeder with optical encoder |

|

Minimum wire feeding length detection |

2 mm wire feeding |

|

Aluminum wire diameter |

125~500μm |

|

Aluminum wire coil size |

Outer diameter: 50~120mm |

|

Inner diameter: 10~11mm |

|

|

Width: 22~45mm |

|

|

Display |

17-inch color display |

|

Visual system |

Image recognition system |

|

Communication method |

IO communication, network port communication |

|

Size(L*W*H) |

1300*1300*1650mm |

|

Net weight |

500KG |

Contact: Rudy Yan

Phone: 0086- 188 0506 7911

Tel: 0086-592-7297239

Email: rudy@winack.com

Add: WinAck Group, Xiangbei Industrial Zone, Xiamen City, China