1. Product description:

The laser cutting machine for metal sheet replaces the traditional stamping die with a laser, which can perform fast and precise cutting of any graphics according to the CAD drawing without the need for a die. No mold is required, and for sample cutting and small batch cutting, the cost is low and the cutting speed is fast. Laser cutting machines are widely used in the battery pack assembly and manufacturing industry, such as special design nickel strip, specifically designed battery cell-to-cell connectors, specifically shaped battery tabs, specifically shaped battery busbars, etc.

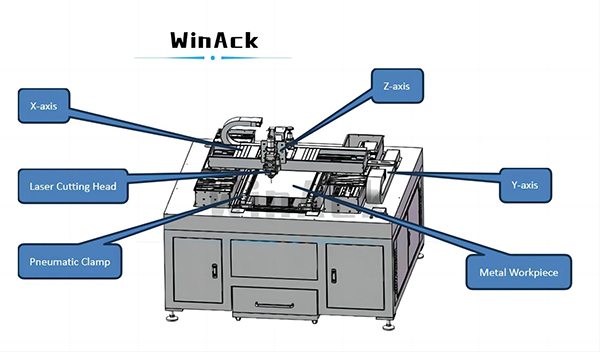

The laser cutting machine is mainly composed of CW fiber laser, laser cutting head, industrial PC, monitor, pneumatic clamp, gas blowing device, three-axis cutting workstation, and water chiller, etc.

2. Features:

a) The laser cutting machine adopts a fully enclosed cutting control system and a non-contact height tracking system, which responds quickly and accurately and is not affected by the shape of the workpiece. It can process any graphics with high precision and fast speed.

b) The laser cutting machine adopts an integrated marble platform frame design and a magnetic levitation linear motor platform, which has a reasonable structure, safety and reliability.

c) The laser cutting machine is equipped with professional CAM software, which is powerful, stable in operation, simple to operate and easy to learn.

d) The laser cutting machine supports the import of CAD drawings, and both .dxf and .dwg format files are supported.

e) The moving guide rail of the laser cutting machine adopts fully enclosed protection to reduce dust pollution and extend the service life of the machine.

f) The laser cutting machine does not require molds and can perform precision cutting according to CAD drawings. Sample cutting and small batch cutting are low-cost and fast.

3. Scope of application:

The laser cutting machine is suitable for precision cutting of metal sheets and metal coils such as bronze, brass, copper, pure nickel, nickel-plated steel, stainless steel, and aluminum, etc.

4. Technical parameters of laser cutter:

Product name | Laser Cutting Machine for Metal Sheet |

Product model | WA-LC-RM1000S |

Laser cutting travel | X-axis: 400mm (Customizable) |

Y-axis: 600mm (Customizable) | |

Repeat positioning accuracy: ±0.005mm | |

Cutting accuracy: ±0.05mm | |

Laser cutting speed | ≤14m/min |

Operation method | Industrial PC & Monitor |

Drawing format | Supports importing .dwg and .dxf format drawings. |

AC input power | Three-phase 380VAC±10% / 50Hz (Customizable) |

Power consumption: ≤3000W | |

Input compressed air source | ≥0.6MPa |

Gas blow protection | The laser cutting machine has a reserved gas blow protection interface. Note: The protective gas source needs to be connected by the user, compressed air or compressed nitrogen, pressure ≥1.0MPa. |

Dust collector (Optional) | The laser cutting machine has a dust collection interface reserved. Note: Dust collector is available at extra cost. |

Reference Dimensions (W*D*H) | About 1500*1450*1800mm |

Reference Weight | About 1000kg |

CW Fiber Laser | |

Nominal power | 1000W (Customizable) |

Power tunability | 10%~100% |

Operation mode | CW/Modulated |

Polarization | Random |

Laser wavelength | 1080 ± 10 nm |

Power stability | ±1 % |

Cooling method | Water cooling |

Laser cutting capabilities (Customizable) | Bronze: T≤3mm |

Brass: T≤3mm | |

Pure nickel: T≤3mm | |

Stainless steel: T≤3mm | |

Copper: T≤0.5mm | |

Etc. | |

Kindly reminder: Increasing laser power can improve cutting capabilities. We will configure the system of the laser cutting machine according to the specific material and thickness.

5. Main configuration of laser cutting machine:

Items | Specification | Brand | QTY |

CW fiber laser | 1000W | Maxphotonics | 1 |

Laser cutting head | FL150 | Empower | 1 |

Laser cutting machine tool | Marble platform machine tool | Customized | 1 |

Linear motors and drives for X-axis | Magnetic levitation linear motor | Akribis | 1 |

Linear motors and drives for Y-axis | Magnetic levitation linear motor | Akribis | 1 |

Linear motors and drives for Z-axis | Magnetic levitation linear motor | Panasonic | 1 |

Ball screw rod | / | HIWIN | 1 |

Control systems and software | / | BOCHU | 1 |

Industrial PC | / | DELL | 1 |

Monitor | / | DELL | 1 |

Pneumatic clamp | / | Customized | 1 |

Water chiller | BD-LW52-HNB-SWSK | BODING | 1 |

Kindly reminder: If the above brand components out of stock, we will change with same class ones instead without information to customer, thus not influence the delivery time. Hope for understanding!

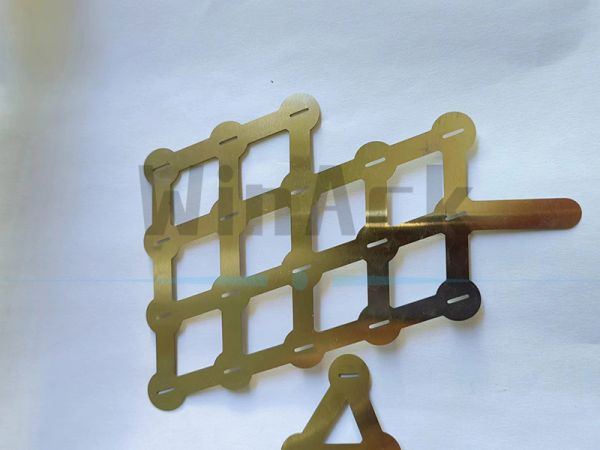

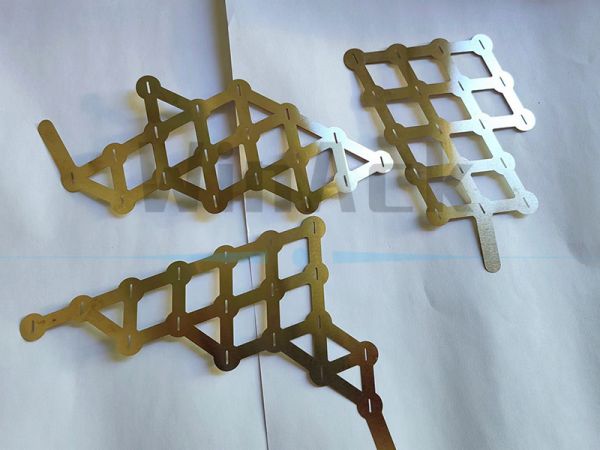

6. Reference picture laser cutting metal:

Figure 1. Special Design Nickel Strip

Figure 2. Specific Shaped Battery Cell-to-cell Connectors

Figure 3. Customized Battery Busbar

7. Reference picture of the laser cutting machine:

Figure 4. Laser Cutting Machine for Metal Sheet

* Reference picture (Picture just as reference, please in kind prevail)

Figure 5. Laser Cutting Machine for Brass Bronze Copper Nickel Aluminum Steel

* Reference picture (Picture just as reference, please in kind prevail)

Contact: Rudy Yan

Phone: 0086- 188 0506 7911

Tel: 0086-592-7297239

Email: rudy@winack.com

Add: WinAck Group, Xiangbei Industrial Zone, Xiamen City, China